Resistance welding / Micro welding

AVIO application and service centre

Our application and service centre in Baden-Dättwil, Switzerland offers professional advice and support.

Our free-of-charge service will find optimal solutions for your individual tasks in the fields of pulse heat soldering and/or resistance welding/micro welding.

Based on your sample parts, our experts will work with you to define and qualify the correct product.

We will then send you a short test report, as well as a suitable implementation proposal.

Take advantage of this service and send us your sample.

AVIO seam welder NAW-2000

Seam welder for hermetic sealing of component housings

With this semi-automatic machine, components such as crystal devices, microwave devices and image sensors can be hermetically sealed in a nitrogen atmosphere. The NAW-2000 „platform“ is suitable for R&D work as well as for producing small to medium-sized series.

Features

- Innovative resistance welding technology

- Parallel roll electrodes (for metal or ceramics)

- Processing of different housing forms (round, rectangular or polygonal)

- Preheating chamber for annealing (up to a maximum of 300°C)

- Processing chamber with nitrogen atmosphere (glove box)

- Different operating modes for tacking and welding

- Programming, operation and data export via touch panel

AVIO resistance welder NRW-IN400P

The new generation of inverters combines individuality with powerful performance.

This all-rounder can be used in a wide variety of applications, both as a stand-alone device or as part of an automated in-line solution.

Features:

- Repeatable and precise resistance welding/micro welding for high productivity.

- Fine waveform control via „Freestyle Profiling“ and multi-level programming

- Freely selectable frequency (2, 4, or 5 kHz, which can be stored in the welding programme)

- Multiple control modes: constant current, constant voltage or constant power.

- Real-time monitoring of welding processes.

- Automatic data recording

- High Performance Monitor for visualising and documenting individual parameters and curves.

- „4-in-1“ multi-transformer system to increase productivity

- Data sheet download

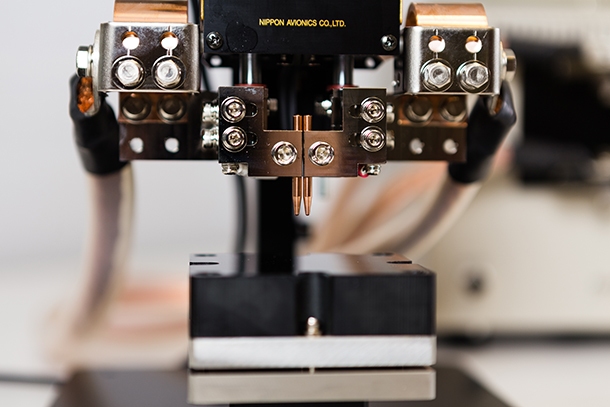

AVIO resistance welding heads

AVIO resistance welding heads and/or micro welding heads are characterised by a compact and precise design.

The different designs include opposed, parallel and parallel/series electrodes.

Depending on the area of application and type, the system heads may be manually or pneumatically operated or motorised, within a pressure range of 0.50 to 1800 N.

Either a compact, handheld digital force gauge (FG-400) or a real-time force monitor with colour display (QC-100 or QC-200) can be used to monitor the displacement.

AVIO electrodes

We offer a wide range of different standard welding electrodes for resistance welding or micro welding processes.

The electrode shape and material should be chosen based on the welding metal. Electrodes in other, customer-specific dimensions and shapes are also available.

We will be happy to assist you in selecting the right electrode and defining bespoke solutions. Contact our experts for advice and we will work together to find the optimal solution for your application.